In preparation to test start the engine, I had a couple of jobs to finish. I made some lower radiator / fan brackets from the inertia reel seatbelt cover that Westfield provide. It’s only thin plastic but will do for now (as I write this, I have the GRP parts to fit). I then attached with the radiator and fan.

Next was to fill with coolant. This was an awkward process as the expansion tank attaches to virtually the lowest point in the system. I filled through here as much as I could, then removed one end of the top radiator hose and filled through there until coolant started to leak from the other open end. I think there will still be some air to come out but it is mostly full. There was a slight leak from the lower radiator hose. This hose seems to be slightly larger than the others but is fine after making the jubilee clip really tight.

Final job was was to attach a ground wire to the fuel tank to prevent static build up.

I checked everything over carefully and then put 5l of petrol into the tank. I checked the fuel system again and all looked fine.

Everything was ready so I turned the ignition on briefly to build fuel pressure. I checked under the car and found a slight fuel leak so tightened this up and it was time to attempt to start the engine….

(Video doesn’t always seem to appear but is also here: https://www.youtube.com/watch?v=cljqbjU4aws)

It works! I stopped working on the car for the evening at this point before something went wrong!

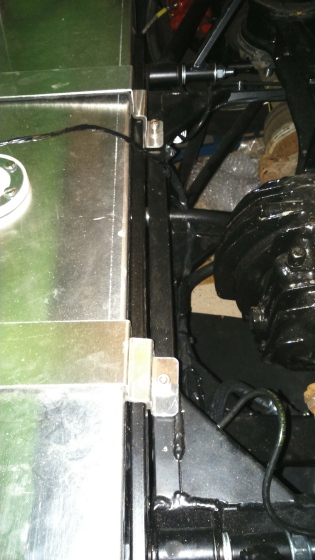

As I had done this with the body clamped in place, now was the time to rivet it in place using special countersunk and larger body rivets.

Slowly looking more like a car…

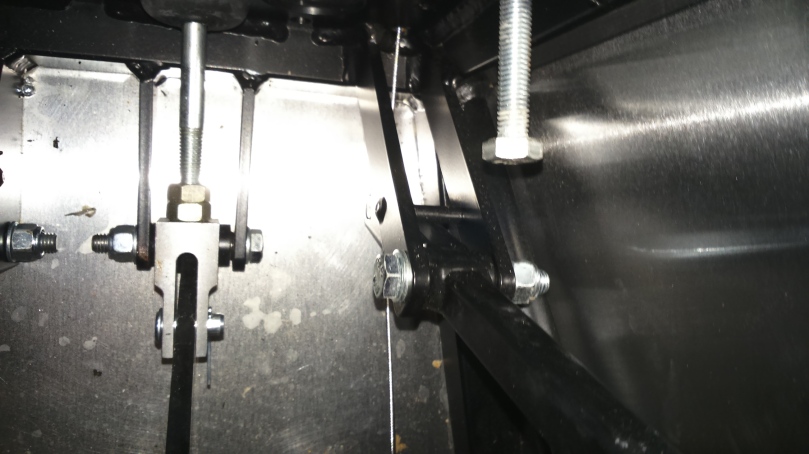

Next was to drill 2 large holes in the scuttle panel for the wiring plus a slot for the steering column, this was then bolted down to the chassis. This took lots of time to get the holes in the right place and get everything lined up properly.

Then with the bonnet in place too:

Doing this made me realise that the intake ducting doesn’t fit with the bodywork in place (without rubbing the brake pipe). Long term I may change to a different filter type and remove this problem but for not, I decided to shorten and glue the plenum which will then give me lots of room. The cross section profile isn’t 100% consistent so there is a bit of a line.

At this point, I also covered the fuel hose and some of the wiring in convoluted tube to protect it. I will finish the wiring at the front once I know it is all working.

Now I am working towards starting the car again and reversing it onto my drive. Then I will let it run for a few minutes to try and bleed the coolant system, ensure the temperature gauge /sensor works before I replace the gauge and check that the fan kicks in once warm. There are quite a few odd jobs to sort out before then but hopefully it will happen in the next couple of weeks.